The EM DTm vertical close-coupled multistage pump from Franklin Electric E-tech with the new inverter device Drive-Tech MINI is an state-of-the-art booster set which combines efficiency, simplicity, innovation and safety.

- Efficiency: The Drive-Tech MINI achieves overall energy savings up to 40 %, compared to conventional speed control systems.

- Simplicity: The Drive-Tech MINI is mounted directly onto the motor control box. It is already supplied with a 2.0 meter power cable and a 1.50 meter cable to connect with the pressure transducer.

- Innovation: The Drive-Tech MINI can be controlled manually by the board panel or via Bluetooth by the Franklin Smartphone App “FE Connect Drivetech” (Android and IOS), enabling you to set and monitor the system remotely, save working data and increase the pump performance.

- Safety: The integrated Class B (EN55011) input-filter prevents any type of disturbances in the domestic network to ensure a reliable use. The filter follows EMC Directives (electromagnetic compatibility).

Features

- Compact close-coupled design, robust and corrosion resistant / Superior efficiency and performances

- Flexible application base plate

- Floating neck ring in PPS

- Oversize motor shaft

- Impellers and diffusers are made of stainless steel in order to achieve durability

- Easy maintenance

- Strong motor rolling bearing fitted in the motor bracket

- Pumping of clear non-loaded fluids

- Mechanical seal Type E0 = carbon/ceramic/EPDM

- Energy saving due to variable speed control

- Soft start and soft stop

- Extended system life and reliability

- Simplified installation on motor or wall

- Easy and fast commissioning thanks to initial configuration wizard

- Installation on humid and dusty environment made possible by IP55 (NEMA 4) protection degree

- High thermal and mechanical performance thanks to aluminum case and independent ventilation

Pump specification

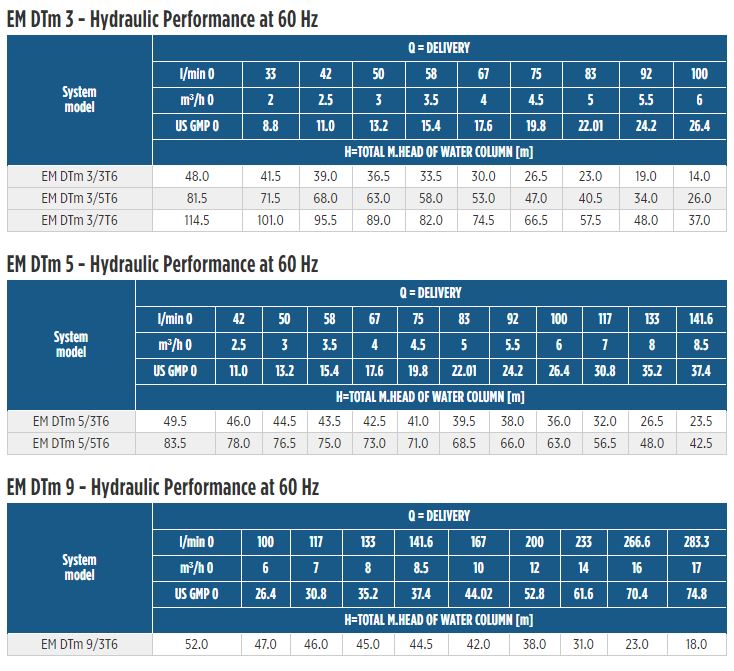

- Flow: up to 17 m³/h

- Head: up to 101 m

- Discharge and Suction port: Threaded or Oval connections

- Maximum working pressure: 10 Bar

- Direction of rotation: clockwise looking at the pump from the top down

- Maximum altitude at rated current: 1000 m

- Maximum ambient temperature 40 °C

- Liquid temperature range:

- Minimum: 0 °C

- Maximum: +80 °C for domestic use (uses covered by CEI EN standard 60335-2-41)

- The hydraulic characteristics are guaranteed, according to ISO standard 9906:2012, grade 3B

For full Drive Tech Mini Specifications please see the technical tab and product sheet download or visit the web page: