Franklin Electric 6″ rewindable motors, manufactured in ISO 9001 certified facilities, are built for dependable operation in 6″ diameter or larger water wells.

Water lubricated thrust and radial bearings enable a maintenance-free operation. A special diaphragm ensures pressure compensation inside the motor. The motor is filled with a special FES93 fluid, providing frost protection down to -15 ºC storage temperature.

The Sandfighter® SiC seal system is the option for sandy applications. For applications in aggressive media, motors made of 316SS and 904L are available.

Specifications:

- Cable material according to drinking water regulations (KTW approved)

- Sand slinger and mechanical seal for high performance in sand

- High efficiency electrical design for low operation cost

- All motors prefilled and 100 % tested

- Max. storage temperature -15 °C – + 60 °C

- Design for retrofitable PT100 sensor

- Approved Franklin Electric Kingsbury type thrust bearing

- Non contaminating FES 93 filling

- Sand fighter® SiC seal system is standard

- Standard Motors complete 304SS

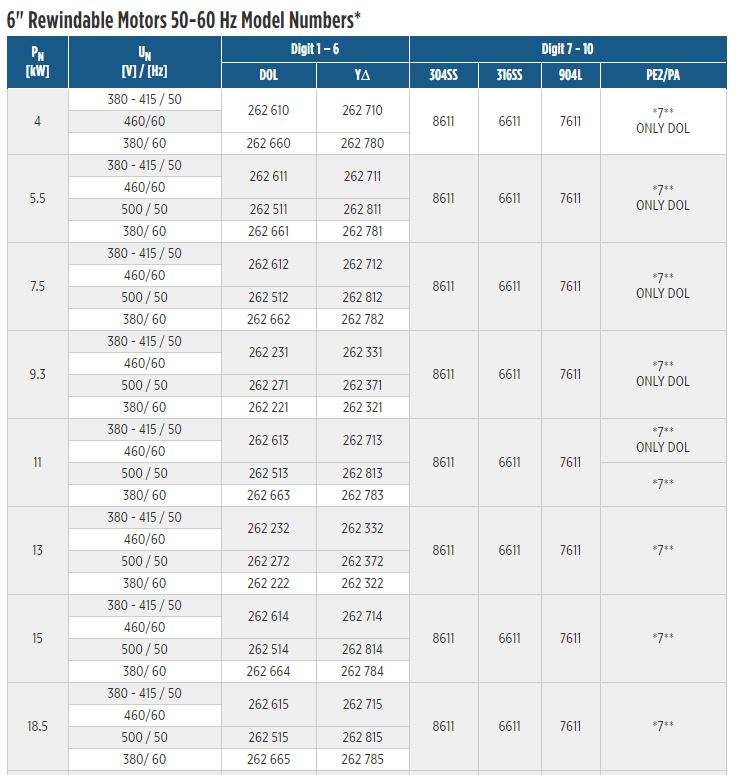

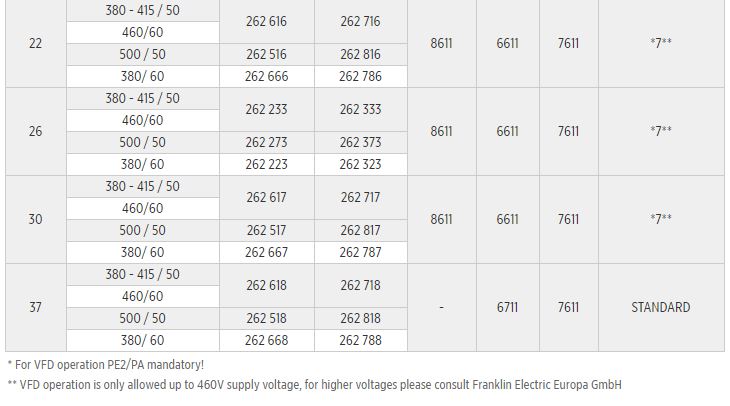

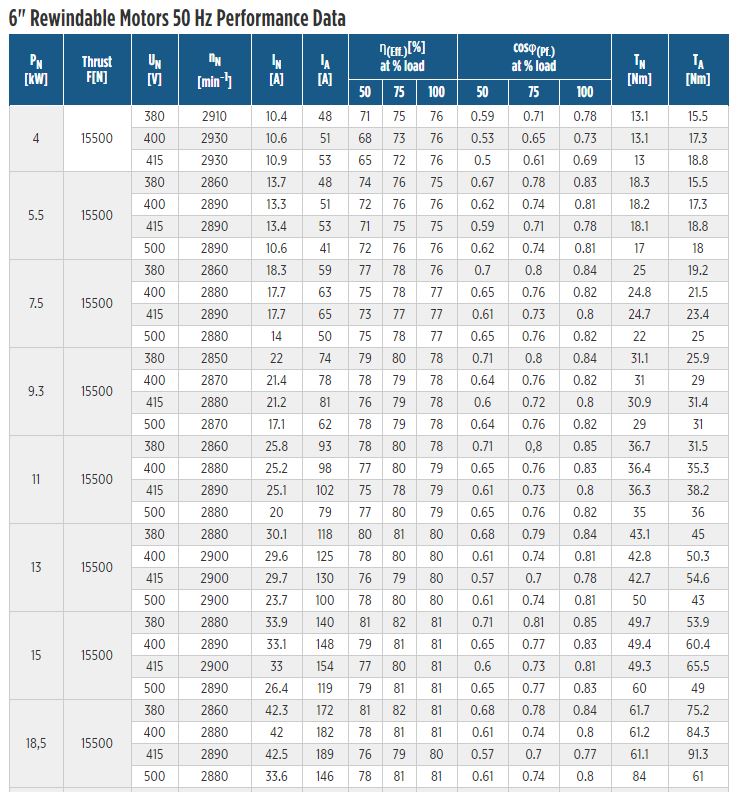

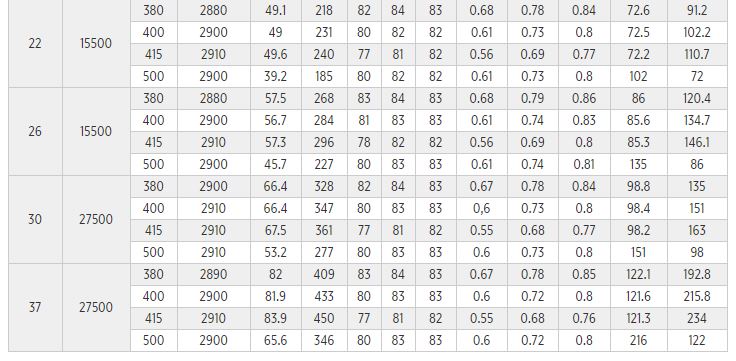

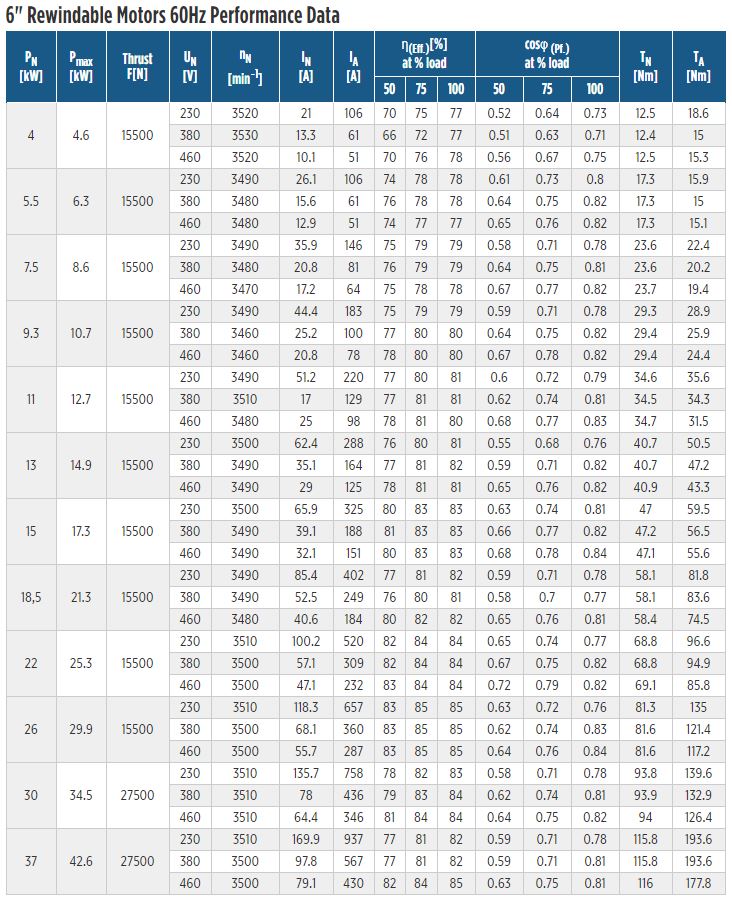

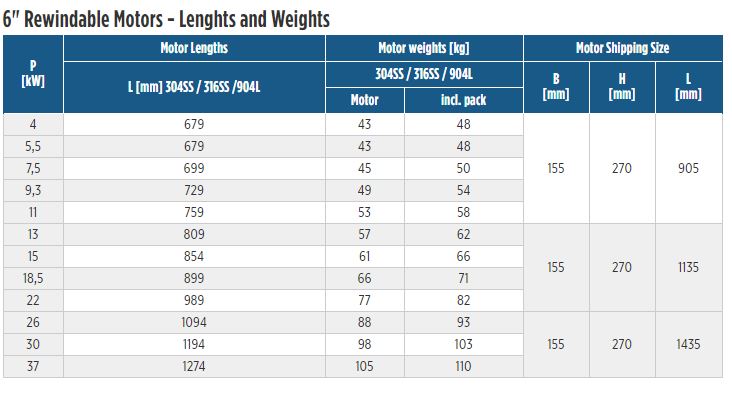

Technical Specifications:

- 6-inch NEMA flange with Studs (M 12)

- Protection: IP 68

- Starts per hour: max. 20

- Installation position: vertical / horizontal (37 kW motors may not be installed horizontally)

- Motor Lead in 4 m length (KTW approved)

- Voltage tolerance 50 Hz: +6 % / -10 %

- (Standard: 415 + 6 % = 440 V, 380 – 10 % = 342 V)

- Voltage tolerance 60 Hz: +/-10 %

- Standard: 460 + 10 % = 506 V, 460 –10 % = 414 V)

- Motor protection: Select thermal overloads according to EN 61947-4-1

- DOL / YΔ – start (pos. of cables 90 °C)

- Standard motor with PVC winding insulation (37 kW in standard with PE2/PA insulation) for max. ambient temp. of 30 ºC with a min.cooling flow:

- 4 kW – 15 kW v = 0.2 m/s

- 18.5 kW – 37 kW v = 0.5 m/s

Options

- Other voltages

- Motors in complete 316SS and 904 L

- Motors up to 30kW with PE2/PA winding insulation for max. ambient temp. of 50 °C at the same cooling conditions as standard (37 kW max. 4 5°C)

- PT 100 temperature sensor (sold separately)

- Lead in different lengths up to 50 m